Explain the classification of elastic webbing in detail

Many people know the elastic webbing, but they don’t know its classification and characteristics very well. In fact, various yarns are used as raw materials to make narrow fabrics or tubular fabrics. However, it is widely used in various industrial sectors such as apparel, shoe materials, luggage, industry, agriculture, military supplies, and transportation.

Classification of elastic webbing

Classified by material

1. Nylon/Tedron/PP polypropylene/acrylic/cotton/polyester/gold and silver onion/hydrogen fiber/light silk/rayon, etc.

2. The distinction between nylon and PP webbing: Generally nylon webbing is woven first and then dyed, so the color of the yarn after cutting will become white due to uneven dyeing, while PP webbing is dyed first and then woven, so there will be no whitening The phenomenon. Compared with PP webbing, nylon webbing is shiny and soft, and can be distinguished by chemical reaction of burning, so the price of nylon webbing is higher than that of PP webbing.

3. Tetoron webbing is relatively soft and has no luster.

4. Acrylic webbing is composed of two materials: Tetoron and cotton.

5. The price of cotton webbing is generally higher.

According to the knitting method

There are several types of plain weave, twill weave, satin weave and mixed weave.

(Plain/small corrugated/twill/safety webbing/pit pattern/bead pattern/jacquard and other PP webbing can be divided into 900D/1200D/1600D according to the thickness of the yarn; at the same time, we should pay attention to the thickness of the webbing, and the thickness also determines its unit price and toughness. degree.)

According to the nature of use

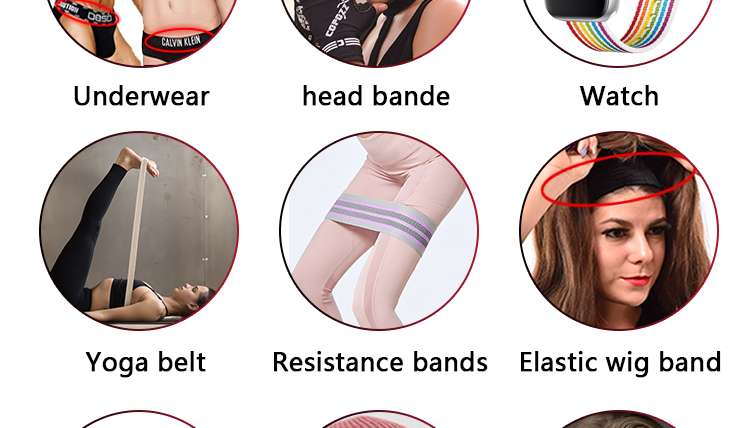

Garment webbing, shoe webbing, luggage webbing, safety webbing, other special webbing, etc.

According to the characteristics of the ribbon itself

It can be divided into elastic webbing and rigid webbing.

According to the process

According to the process, it is divided into two categories: woven belt and knitted belt. The webbing, especially the jacquard webbing, is similar to the cloth label process, but the cloth label warp yarns are fixed, and the pattern is expressed by the weft yarn; while the basic weft yarn of the webbing is fixed, and the pattern is expressed by the warp yarn. A small machine is used. It may take a long time to thread the yarn and adjust the machine, and the efficiency is relatively low.

But it can produce a wide range of dazzling products, not always those faces like cloth labels. The main function of the webbing is decorative, and some are functional. Such as popular mobile phone straps. After the tape is woven, various characters/patterns can be screen-printed, which is generally cheaper than knitting the characters and patterns directly.

Shuttle webbing is mainly divided into two categories: non-shuttle webbing and shuttle webbing. At present, the use of shuttleless webbing is more common than shuttle webbing.

According to characteristics

1. Elastic band: hook side band/wired elastic band/twill elastic band/towel elastic band/button elastic band/frame elastic band/non-slip elastic band/jacquard elastic band.

2. Rope and belt: round elastic rope / needle pass, PP, low elasticity, acrylic, cotton, hemp rope, etc.

3. Knitted belt: due to its special structure, it refers to the horizontal (dimensional) elasticity, and is mainly used for piping knitted belts.

4. Letter belt: polypropylene material, letter lifting, double-sided letter, letter lifting round rope, etc.

5. Herringbone belt: transparent shoulder belt, gauze belt, thread belt.

6. Luggage webbing: PP belt, nylon edging belt, cotton webbing, rayon webbing, acrylic webbing, jacquard webbing.

7. Velvet belt: elastic velvet belt, double-sided velvet belt.

8. All kinds of cotton edges, lace edges.

9. Velvet belt: The velvet belt is made of velvet, with a thin layer of hair inlaid on the belt.

10. Printed belt: various patterns are tailored on the belt.

11. Ribbon with ears: suitable for women’s dresses (hanging ears), sweater tops and necklines, cuffs, etc.